Natural Wood Pulp Compressed Wooden Cellulose Fiber Use for Concrete/ Mortar/ Plaster/ Tile Adhesive

Basic Info.

| Trademark | OEM |

| Origin | China |

| Production Capacity | 5000ton/Year |

Product Description

DESCRIPTION

cellulose fiber Is a kind of high strength and hydrophilic fiber, extracted from special plant.It can form a better bonding in the concrete and cement . Because of the short fiber filament diameter , so it accupy a huge volume in unit volume, improve the crack resistance of concrete.It is very easy to disperse in concrete, and the dispersed fibers will not agglomerate again. The addition of reinforced cellulose fiber has no effect on the workability of the concrete mixture. It solves the persistent problem of polypropylene fiber reducing the slump of concrete in one fell swoop, In addition to controlling the micro-cracks caused by plastic shrinkage, drying shrinkage, temperature changes and other reasons of concrete, this fiber product can prevent and inhibit the formation and development of cracks, and greatly improve the concrete's impermeability, freeze-thaw resistance and other general fiber advantages. It is a super partner of high-performance concrete.Cellulose fiber Contains a unique cavity, which can store part of the free water in the early stage of hydration, delay the generation of hydration heat peak, reduce the temperature gradient, reduce the evaporation of water, and greatly reduce risk of the early concrete cracking due to temperature drop and other shrinkage.When the cement hydration continues to consume water, the concrete tends to be dry and the humidity decreases, which promotes the release of free water in the fiber cavity, promotes cement hydration, improve the density of concrete. At the same time its resistance to chloride ion erosion, sulfate erosion, resistance to carbonization and other durability are significantly improved

SPECIFICATION

| Density (g/cm3) | 1.1 | The average length ( Mm ) | 2.1 |

| Diameter ( μ M ) | 18 | Surface area ( CM 2 /g ) | 25000 |

| (Daniel G/9000m ) | 2.5 | The tensile strength ( Mpa ) | 600-900 |

| Fiber spacing | 660 | Elastic modulus ( GPa ) | 8.5 |

| The number of fibers per cubic concrete | 1.4 Billion | Hydrophilic | good |

ADVANTAGE

Prevent the shrinkage of concreteImprove the crack resistance of concreteGreatly improve the workability of fIBERImprove the durability of concreteImprove the mechanical character of concrete

APPLICATION

A: Manufacturer, welcome to our factory

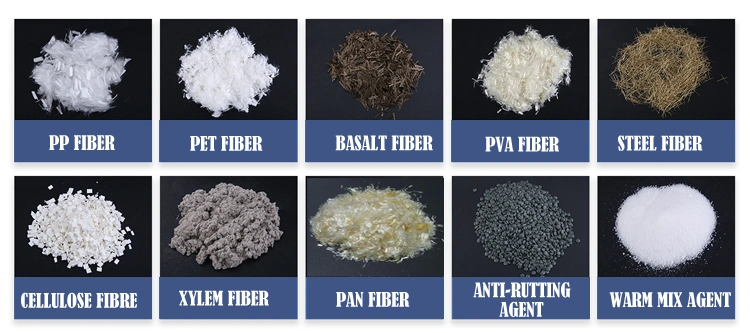

Q: What are your products?

A: Polypropylene fiber, Polyester fiber, polyacrylonitrile fiber, PVA fiber, plastic steel fiber, anti-crack fiber, wood fiber, cellulose fiber, glass fiber, Steel fiber, carbon fiber, colorful wall coating fiber, anti-rutting agent, PSBR high modulus asphalt additive, asphalt warm mix agent, asphalt flame retardant, asphalt modifier,Anti-stripping agent, Sun shading mesh

Q: Are the samples free?

A: Accept free sample test, buyer bear delivery charge

Q: How can we guarantee quality?

A: Always a pre-production sample before mass production;

Always final Inspection before shipment;

Q: What are your MOQ?

A: 1000KG Or More than 1000USD per order

Q: What is your delivery time?

A:Production will be arranged after receiving the deposit, and shipment will be arranged after all payments are made. The delivery time is about 10-15 working days.